Opening Resilience: The Significance of High Quality Undercarriage Parts in Building

Opening Resilience: The Significance of High Quality Undercarriage Parts in Building

Blog Article

Optimize Performance With Durable Undercarriage Components

In the realm of hefty machinery and tools, the function of undercarriage components is vital in guaranteeing optimum performance and long life. The effectiveness and effectiveness of these elements can significantly affect the overall procedure of machinery, making the choice of durable undercarriage components an essential choice for operators and supervisors alike. By discovering the intricate partnership between toughness and performance in undercarriage parts, a much deeper understanding of the subject arises, dropping light on the crucial factors that drive functional success. As we browse through the complexities of undercarriage upkeep, longevity, and element choice, a thorough expedition awaits to introduce the key techniques for accomplishing peak efficiency in sturdy applications.

Benefits of Utilizing Resilient Undercarriage Parts

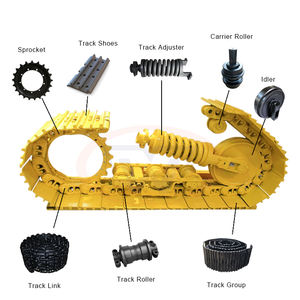

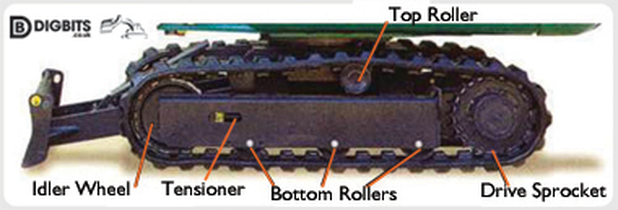

Making use of resilient undercarriage components not only improves the durability of heavy machinery however also reduces maintenance costs significantly. By purchasing top quality undercarriage components, such as tracks, sprockets, idlers, and rollers, equipment drivers can experience raised uptime and enhanced general performance.

Additionally, the long life of heavy machinery is directly connected to the top quality of its undercarriage components. Resilient elements can stand up to the roughness of demanding applications, guaranteeing that the devices continues to be functional for extensive periods. Because of this, operators can prevent expensive downtime and upkeep costs, ultimately optimizing the return on financial investment for their equipment.

Factors Impacting Undercarriage Sturdiness

The toughness of undercarriage parts in hefty equipment is influenced by numerous important elements that directly influence performance and long life. Top notch materials, such as hard steel, are necessary for enduring the severe conditions and hefty tons that undercarriage parts are subjected to - undercarriage parts.

Additionally, environmental variables can have a considerable effect on the durability of undercarriage parts. Direct exposure to abrasive products, extreme temperatures, and harsh working conditions can increase deterioration on undercarriage parts. Choosing undercarriage components that are specifically created to withstand these environmental obstacles is vital for making sure longevity.

Additionally, the style and design of undercarriage components have a straight impact on their durability. Parts that are developed to distribute tons uniformly, lower rubbing, and decrease stress concentrations are much more likely to have a longer lifespan - undercarriage parts. By thinking about these vital aspects, devices drivers can make best use of the durability and performance of their undercarriage parts

Upkeep Tips for Prolonging Undercarriage Life

Carrying out normal upkeep routines is vital for prolonging the lifespan of undercarriage components in heavy equipment. To lengthen the undercarriage life, it is vital to often check for deterioration. Frequently look for loose or absent screws, harmed rollers, or misaligned tracks, as these problems can escalate and cause more damage if not addressed without delay. In addition, guarantee that the undercarriage is correctly lubricated according to supplier guidelines to reduce rubbing and stop premature wear.

One more vital upkeep tip is to maintain the undercarriage clean from dust, rocks, and debris. Build-up in the undercarriage can speed up wear and deterioration, resulting in pricey repair work. Cleaning the undercarriage after operation in rough conditions is suggested to stop these problems.

Lastly, tracking and recording upkeep activities can assist in developing a proactive upkeep timetable. Keeping in-depth records of assessments, fixings, and replacements can give valuable insights into the undercarriage's problem and efficiency with time, aiding in predicting and avoiding prospective failings. By adhering to these upkeep pointers diligently, operators can considerably boost the toughness and weblink efficiency of undercarriage components in hefty equipment.

Picking the Right Undercarriage Elements

Choosing appropriate undercarriage parts is important for making the most of the performance and longevity of hefty equipment. When it comes to selecting the right undercarriage parts, there are several variables to think about.

Choosing for trustworthy brand names known for producing resilient and high-performance undercarriage components can substantially influence the total performance and long life of the equipment. By carefully selecting the right undercarriage components, equipment owners can enhance productivity, reduce downtime, and expand the life-span of their hefty equipment.

Case Researches: Enhanced Performance With Long Lasting Parts

Including long lasting undercarriage parts has actually demonstrated substantial enhancements in equipment performance. One case research study involved a building and construction company that updated its excavator's undercarriage components to extra long lasting options. The business observed a notable decrease in downtime due to undercarriage maintenance, causing enhanced performance and expense financial savings. The resilient components withstood extreme working conditions, minimizing damage considerably.

In one more circumstances, a mining procedure changed the undercarriage parts of its bulldozer with top notch, durable alternatives. This switch caused an impressive improvement in the bulldozer's maneuverability and general efficiency. The equipment can browse difficult surfaces more effectively, bring about boosted functional efficiency and reduced fuel consumption.

In addition, a logging business invested in durable undercarriage components for its forestry devices. These case studies emphasize the concrete benefits of making use of long lasting undercarriage parts in optimizing equipment performance and long life.

Final Thought

Finally, utilizing sturdy undercarriage parts can significantly boost performance and long life of heavy machinery. Aspects such as proper upkeep and selecting the right parts play an important role in making best use of Go Here undercarriage sturdiness. By implementing these approaches, companies can lower downtime, boost performance, and eventually reduce operational expenses. Study have actually shown that buying durable undercarriage components can bring about enhanced total performance and efficiency in numerous industries.

The performance and effectiveness of these components can substantially affect the total procedure of machinery, making the selection of long lasting undercarriage components a critical decision for operators and managers alike.Integrating sturdy undercarriage components has actually shown significant enhancements in machinery performance. These case research studies highlight the concrete advantages of utilizing long lasting undercarriage components in maximizing equipment efficiency and durability.

In final thought, using long lasting undercarriage components can substantially boost efficiency and durability of heavy machinery (undercarriage parts). Instance research studies have actually revealed that spending in long lasting undercarriage parts can lead to discover this info here enhanced general efficiency and performance in different sectors

Report this page